by Lynn Yarris

The world record for field strength in a

dipole magnet has been shattered by researchers at Berkeley Lab. A

one-meter long superconducting electromagnet, featuring coils wound out

of 14 miles of niobium-tin wire, reached a field strength as high as

13.5 Tesla, far surpassing the previous high of 11.03 Tesla set by a

Dutch group in 1995.

The world record for field strength in a

dipole magnet has been shattered by researchers at Berkeley Lab. A

one-meter long superconducting electromagnet, featuring coils wound out

of 14 miles of niobium-tin wire, reached a field strength as high as

13.5 Tesla, far surpassing the previous high of 11.03 Tesla set by a

Dutch group in 1995.

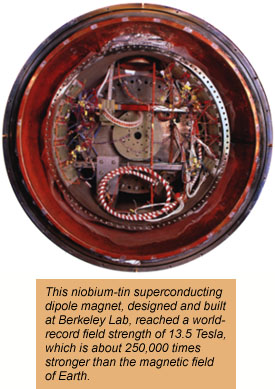

The team that designed, built and tested the new record-holding magnet was led by Ron Scanlan, a materials scientist with Berkeley Lab's Accelerator and Fusion Research Division. The field strength achieved by Scanlan and his group is about a quarter of a million times stronger than the magnetic field of Earth and about triple the strength of the superconducting dipole magnets at the Tevatron, the highest energy particle accelerator in the world.

The new magnet is among the first to use a niobium-tin alloy for the superconductivity (the absence of electrical resistance) of its coils. Construction costs for this prototype were so high - about one million dollars - that only one magnet could be built and tested. This was a nerve-wrenching departure from the conventional practice of building several test magnets at once.

"We were in unknown territory and even though we carefully tested all of the components during construction, we could not know for certain what we had until we tested the completed magnet," Scanlan says. What he and his group have will likely serve as the model for the dipole magnets that will be used in the next generation of high-energy particle accelerators. This particular new dipole magnet will be used at Berkeley Lab as a test facility for evaluating superconductors that could yield even more powerful magnets in the future.

Dipole magnets are used to bend and maintain the path of accelerating particle beams. The higher the field strengths of the magnets, the tighter the arc of the beam. With stronger dipole magnets, an accelerator can push particles to much higher relativistic energies around the same-sized circular beam path. The use of high-field strength superconducting electromagnets has always been a considerable technical challenge, however, because superconductivity has a tendency to weaken and disappear in the presence of a strong magnetic field. Nonetheless, the inherent limitations of conventional electromagnets - they cannot attain a dipole field strength much above 2 Tesla - has prompted a continuing development of new and better superconducting alloys.

In recent years, the alloy of choice for accelerator magnets has been niobium-titanium. Superconducting magnets made from this alloy operate in all of today's most powerful machines and will be used in the Large Hadron Collider (LHC) now being built at CERN. The LHC magnets are expected to operate at a field strength of 8.6 Tesla which is approaching the 10 Tesla mark that is considered to be the upper limit of niobium-titanium accelerator magnets.

In the search for superconductors capable of reaching higher field strengths, it was determined that niobium-tin could, in principle, fit the bill. However, unlike niobium-titanium, niobium-tin is a non-ductile material, and was thought to be too fragile and brittle to withstand the stress of fabrication.

Scanlan and his group overcame the brittleness obstacle by making their cable from separate strands of niobium and tin in a copper composite strand (fabricated by the companies of Intermagnetics General and Teledyne Wah Chang) while the materials were still ductile. Only after they wound their cable into four magnet coils did they meld the separate niobium and tin strands into the superconducting compound that is so brittle. The alloy was made by heating the coils to 950 Kelvins (about 680 degrees Celsius), baking them for about ten days, then cooling the material to ambient temperature. Once the four coils were assembled into a dipole magnet they had to be cooled far below room temperature to make them superconducting, this time to a temperature of about 4.3 Kelvin (-270 degrees Celsius). "The thermal expansion-contraction effects in going from a reaction temperature of 950 K to a test temperature of 4.3 K are enormous," says Scanlan. To withstand this and other stresses, the wound coils are impregnated

After being filled with epoxy, each coil is encased in an iron yoke that contributes to the strength and stability of the magnetic field. The coils are then wrapped in 18 layers of sheet stainless steel, forming a collar that prevents the coils from separating under the force generated when their tremendous magnetic field is energized. The finished meter-long magnet is also about one meter in diameter and has a 50 millimeter bore. It weighs about seven tons.

"Inside the iron yoke and stainless steel wrap of each coil is something that is as brittle as glass," says Scanlan, explaining why, despite its bulk and solid appearance, the magnet has to be handled with great care when it is moved from one location to another.

As with any new superconducting electromagnet, the niobium-tin dipole at Berkeley Lab had to be "trained" to attain its peak field strength. Training is a staggered process in which the magnet is chilled until its coils become superconducting (using liquid helium) then energized up in field strength until superconductivity is lost in some parts of its coils through inadvertent warming. This temporary loss of superconductivity is called "quenching" and when it occurs, the magnet must be given time to recover, then re-cooled.

"The magnet was ramped to slightly above 10 Tesla before the first quenching occurred," says Scanlan, calling this initial effort "encouraging." The magnet was then slowly but steadily trained upward in field strength until, after 13 quenches, it reached 11.14 Tesla. When further training at 4.3 Kelvin failed to raise the field strength, Scanlan and his group began lowering the temperature. Field strength maxed out at the 13.5 Tesla mark after the temperature had been dropped to about 1.8 Kelvin (-271 degrees Celsius). The entire process lasted about three weeks.

"This became a test of the magnet's structural integrity as well as its field strength because of the stress involved," Scanlan says. "Any weakness in the structure would have caused the entire magnet to fail."

The definition of a good magnet is one that stays trained, according to Scanlan. Consequently, his team is now in the process of allowing the magnet to warm to room temperature before cooling it back down and ramping it up again. Based on performances during the earlier training session, the magnet is expected to do fine. Eventually, Scanlan says, his group will disassemble their magnet and rebuild it with an eye toward bringing expenses down so future production costs will be comparable to those of today's niobium-titanium magnets.

In addition to Scanlan, other members of Berkeley Lab's superconducting magnet team included Bob Benjergerdes, Paul Bish, Shlomo Caspi, Ken Chow, Dan Dietderich, Domenico Dell'Orco, Roy Hannford, Warren Harnden, Hugh Higley, Alan Lietzke, Alfred McInturff, Larry Morrison, Mike Morrison, Clyde Taylor, and Johannes Van Oort.