|

|

| |

|

|

|

| |

|

| |

|

| |

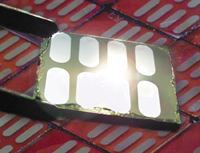

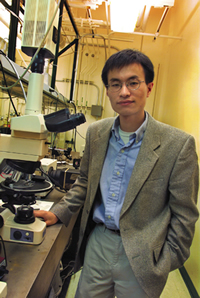

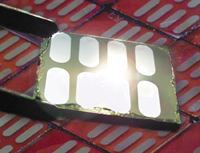

Above: Chemist Paul Alivisatos, director

of Berkeley Lab's Molecular Foundry, in his laboratory

where he and his team developed a hybrid semiconductor

and plastic solar cell (top). The tiny solar cell assemblies

were created using nanoscale rods of cadmium selenide

and the P3HT polymer. Such cells will be cheaper and easier

to make than their semiconductor counterparts. |

| |

|

The hybrid solar cells were developed by Paul Alivisatos,

a chemist who holds a joint appointment with Berkeley Lab's

Materials Science Division (MSD) and UC Berkeley's Chemistry

Department, along with Janke Dittmer, an MSD staff scientist,

and UC Berkeley graduate student Wendy Huynh. The researchers

believe their hybrid cell will be cheaper and easier to make

than its semiconductor counterparts and offer the same nearly

infinite variety of shapes as pure polymers.

"We have demonstrated that semiconductor nanorods can

be used to fabricate readily processed and energy-efficient

hybrid solar cells together with polymers," says Alivisatos,

director of the Molecular Foundry, a center for nanoscience

now being established at Berkeley Lab.

At the heart of all photovoltaic devices are two separate

layers of materials, one with an abundance of electrons that

functions as a "negative pole," and one with an

abundance of electron holes (vacant, positively-charged energy

spaces) that functions as a "positive pole." When

photons from the sun or some other light source are absorbed,

their energy is transferred to the extra electrons in the

negative pole, causing them to flow to the positive pole and

creating new holes that start flowing to the negative pole.

This electrical current can then be used to power electronic

devices.

In a typical semiconductor solar cell, the two poles are

made from n-type and p-type semiconductors. In a plastic solar

cell, they're made from hole-acceptor and electron-acceptor

polymers. In their new hybrid solar cell, Alivisatos and his

colleagues used the semicrystalline polymer known as poly(3-hexylthiophene)

or P3HT for the hole acceptor or negative pole, and nanometer-sized

cadmium selenide (CdSe) rods as the positive pole.

"With CdSe rods measuring 7 by 60 nanometers, our hybrid

solar cells achieved a monochromatic power conversion efficiency

of 6.9 percent, one of the highest ever reported for a plastic

photovoltaic device," says Alivisatos.

Even so, Alivisatos says that many engineering tricks can

be applied to make future versions of the hybrid solar cells

much more efficient.

Growing Striped Nanowires

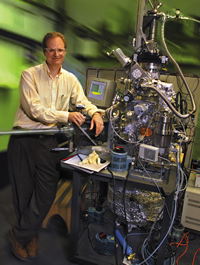

Development of nanowires composed of two different semiconductors

was led by Peidong Yang, a chemist who also holds a joint

appointment with Berkeley Lab's Materials Sciences Division

and UC Berkeley's Chemistry Department. These nanowires are

called "striped" or "superlatticed" because

their semiconductors (silicon and a silicon/germanium alloy)

are arranged in discrete alternating segments. They have potential

because they can function as a transistor, light-emitting

diode, biochemical sensor, heat-pumping thermoelectric device,

or all of the above, along the same length of wire.

|

|

|

|

| |

|

|

|

| |

|

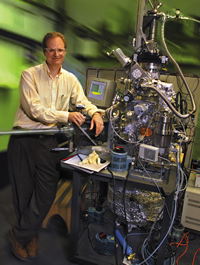

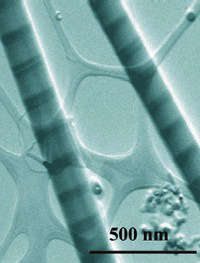

Above: Chemist Peidong

Yang led the development of a new "striped"

nanowire.

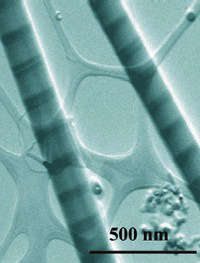

The image at top, taken with a scanning transmission electron

microscope, reveals two nanowires featuring alternating

bands of silicon (light) and a silicon germanium alloy

(dark), which form interfaces that could be made into

transistors, LEDs, and other types of electronic devices.

Each wire is less than a hundredth the diameter of a human

hair. |

|

|

|

"This is a major advancement in the field of one-dimensional

nanostructure research," says Yang. "It gives us

the ability to create various functional devices, such as

a p-n junction, a coupled quantum dot structure, or a bipolar

transistor, on a single nanowire--which can then be used as

a building block for constructing more complex systems."

Microchips have been likened to sandwiches in that they are

made by depositing layers of different types of semiconductors

with different electrical properties on a wafer of silicon.

The interfaces between these different layers control the

flow of electrons and enable transistors and other electronic

components to function. Striped nanowires offer the same electronic

diversity as a two-dimensional microchip in a one-dimensional

nanoscale platform.

Yang and his research team grow their striped wires using

a hybrid "pulsed laser ablation/chemical vapor deposition"

process. A silicon wafer coated with a thin layer of gold

is heated in a furnace so that the gold film forms a liquid

alloy with the silicon and spontaneously breaks up into nanometer-sized

droplets. Vapors of the two semiconductors will then condense

around the gold droplets as deposits which become nanowire

segments. Chemicals are used as the source of the silicon

vapor and a laser is used to vaporize the germanium. When

the laser is off, only silicon is deposited on the gold particles;

when the laser is on, both silicon and germanium are deposited.

"By periodically turning the laser on and off--and this

can be readily programmed--we can form a silicon and silicon/germanium

superlattice on every individual nanowire in a block-by-block

fashion," says Yang. "The entire growth process

resembles the living polymerization synthesis of a block copolymer."

The technique is efficient and cheap. In just one hour, millions

of striped nanowires can be made at relatively small cost.

Working with Yang on the striped nanowire project were UC

Berkeley graduate students Yiying Wu and Rong Fan.

-- Lynn Yarris

|