n the Indoor Environment Program we did research on home air leakage and, somewhat to our surprise, found that 20 percent of leakage is through the heating and cooling ducts," says Mark Modera of the Environmental Energy Technologies Division. He notes that the problem is bigger than waste energy alone. Leaky ducts contribute to uneven room temperatures and excess humidity; they can admit chemical fumes, auto exhaust, and radon gas.

n the Indoor Environment Program we did research on home air leakage and, somewhat to our surprise, found that 20 percent of leakage is through the heating and cooling ducts," says Mark Modera of the Environmental Energy Technologies Division. He notes that the problem is bigger than waste energy alone. Leaky ducts contribute to uneven room temperatures and excess humidity; they can admit chemical fumes, auto exhaust, and radon gas.

"But how do you get to the leaks? If you try to fix them from outside, labor is going to run you 80 percent of the cost of repairs," Modera says. "So we tried to figure out a way to get at them from inside. We investigated robots that run through pipelines, applying tape from inside. We looked at telescoping cylinders that can be extended into a pipe. But mechanical fixes like these, whatever their other problems might be, get confused when they come to a T- or a Y-joint in the pipe. We needed an airborne sealant that could flow around bends."

|

(Click on image to enlarge)

|

|

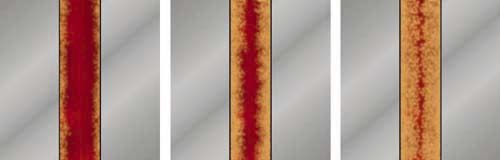

Escaping air under pressure causes polymer particles to stick first to the edges of a leak, then to each other until the leak is closed. This leak, three millimeters wide and 40 millimeters long, was completely sealed in 15 minutes.

|

Such a sealant would have to remain airborne until it encountered a leak and not deposit itself on the duct walls. Liquid runs, so the particles have to be a sticky solid. Too high an air flow, and they would be flung against the walls; too low and they would fall out of the airstream. Modera's group chose a commercially available vinyl acetate.

They designed an injector for the polymer mixture about the dimensions of a big vacuum cleaner. "We needed to create the right flow conditions and use particles of the right size to stay airborne," Modera says. "Air pressure defines air velocity at leaks -- when the air turns a sharp corner, that's where the particles leave the airstream."

Trying to escape through the leak, the particles stick first to the edges of the leak and then to one another. Leaks up to an inch wide can be sealed this way, although cracks up to a quarter-inch wide are the main targets.

In 1995 the aerosol sealing project moved out of the laboratory, and tests were done on over a hundred single-family homes all over the country, in climates from New England to the Gulf Coast to the Nevada desert.

| Lead scientist on this project

|

|

|

|

|

|

Often the first challenge was to persuade home-owners they had a problem. "People don't believe their ducts leak," Modera says. "It's not like water pipes-people don't wake up at night worrying about them. Air is invisible." In fact the energy waste from leaky residential ducts alone is equivalent to the gasoline burned by 13 million cars a year.

To seal the ducts in a house, the floor, ceiling and wall registers are covered so that air in the ducts can escape only through the leaks. Sealant is injected for about an hour.

At the end of that time some 80 percent of the leakage has been sealed; register flows increase up to seven percent. Depending on the type of house and the climate, energy savings can reach several hundred dollars a year.

The aerosol sealant technology is licensed to individual heating, ventilation, and air-conditioning contractors, who receive supplies and equipment - including the laser temperature sensors and the computer which calculates air loss and leakage repair in real time -- and who charge $300 to $600 to fix the duct system in a home, an amount which can be recouped in energy savings within one to three years.

- Paul Preuss

n the Indoor Environment Program we did research on home air leakage and, somewhat to our surprise, found that 20 percent of leakage is through the heating and cooling ducts," says Mark Modera of the Environmental Energy Technologies Division. He notes that the problem is bigger than waste energy alone. Leaky ducts contribute to uneven room temperatures and excess humidity; they can admit chemical fumes, auto exhaust, and radon gas.

n the Indoor Environment Program we did research on home air leakage and, somewhat to our surprise, found that 20 percent of leakage is through the heating and cooling ducts," says Mark Modera of the Environmental Energy Technologies Division. He notes that the problem is bigger than waste energy alone. Leaky ducts contribute to uneven room temperatures and excess humidity; they can admit chemical fumes, auto exhaust, and radon gas.